The clear Nishiki river flows through eastern Yamaguchi prefecture, and branches in two just before it empties into the Seto Inland Sea. This sake brewery where I work, which has made sake for generations, stands on the banks of the Imazu river, one of those branches.

The grounds where our brewery stands once held a storehouse for the Imazu Teahouse. According to historian Miyata Itsumi, “The Imazu Teahouse was a second home for the Kikkawa Daimyo, a port facility, and a government office. When the Daimyo set out by boat, on their procession to Tokyo and so on, they would use this spot as a rest station before boarding or after landing, and when marrying, the bride would arrive by boat and reach land via the gangi (a stair stepped stone landing pier). She would stay a while at the teahouse, and from there leave for the manor. … It was decommissioned in April of the third year of Meiji, and transferred to private ownership.” That private owner was my ancestor.

The founder of Yaoshin, my great-grandfather, repurposed the former rice and washi-paper storehouse into a saké brewery, and began making this drink I still make. The Teahouse’s primary facility for serving as a docking station was the gangi. A gangi is like a set of stone steps leading down into the water serving as a pier or quay connecting the river and the land, where boats could dock. At our founding this gangi was used to unload rice which came down the Nishiki river by boat for use in saké making.

By the time I was born, in 1956, it was no longer used, but my heart will always be tied up at that gangi.

When I was a child, and summer vacation came, I would spend days jumping off the gangi to swim in the river, and played wild games of tag on the landings and the narrow stair lanes parallel to the river, called “dog runs.” In those days, there were fireworks shows on the Imazu river, and the gangi served as seating for crowds of spectators.

In my youth, when I was obsessed with Coltrane, I played the saxophone to the river there. At other times, I sat with friends and shared secrets while we stared into the water. At others, I walked the gangi drunk and almost fell into the water (and sometimes I did fall!). In difficult times, I came to the gangi to heal, and in glad times, I came to the gangi to calm down. It is part of uncountable memories.

When I was in Tokyo for university, the gangi was replaced with concrete as part of a grand scheme for bank reinforcement work to help defend from “once in a century” floods. The old gangi stones were taken away, and one third of its width was replaced with concrete steps mimicking its design. But the now cramped, unsightly riverbank is a pale imitation of what it once was.

Back when the gangi was still there, and the riverbanks were still stone, I remember how crabs would come up from the river and crawl around our house like they owned the place. And we often saw white snakes creep from between the rocks and swim across the water, as well. Which goes to show just how integrated the water and the land ecosystems were at the gangi, demonstrating so clearly how it was a place of growth and life. And so, ever since I came to lead Yaoshin Shuzo, and created the label Gangi, we have made our sake with the belief that “the water’s edge is a place of new life”

Fifth Generation Kuramoto, Yaoshin Shuzo KK

From “Kikkawa Archives Newsletter”

STYLE

Approach Making Saké with Simplicity (Junmai/Muroka)

Gangi’s lineup includes only junmai saké, made only from rice, rice kōji, and water. We do not make honjozo style, which adds brewer’s alcohol to the mix, or need other orthodox saké making methods. Just as a master carver creates a statue from a single tree, we work to bring out the possibilities of our primary ingredient: rice. In addition, although most breweries filter their saké with activated charcoal, we find no need to do it. We have developed a way to finish our saké to such a high degree of quality that there’s no need for any additional processing after pressing. So, we approach saké with simplicity and directness, without the need of any unnecessary adding or removing.

Never Scrimp on Preparation (Washing & Soaking Rice)

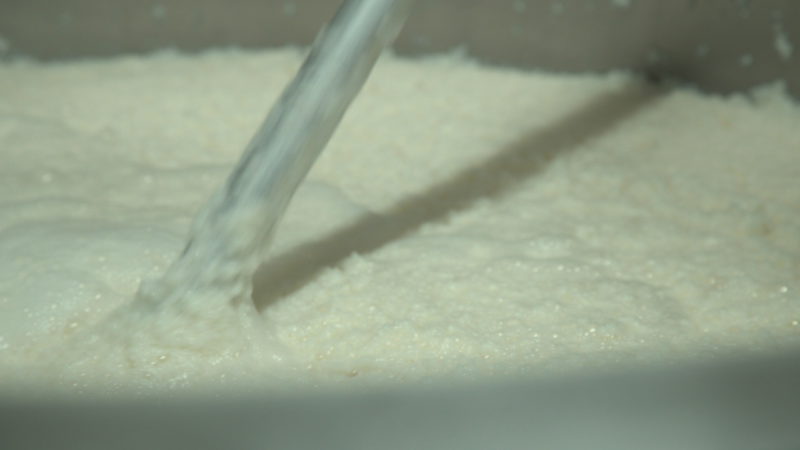

After a game, athletes often say that “It’s time to prepare for our next match.” For them, preparation means things like working on technique and keeping in shape, but in saké making we have to prepare as well. For us, the keys to preparation are washing and soaking the rice.

Good saké starts with good rice kōji and fermentation mash, both of which start with properly steamed rice. Going further, properly steamed rice starts with properly washed and soaked rice. A well-done wash and soak is absolutely essential to start the whole process.

The goal of washing & steeping rice is twofold. First, we remove any remaining mill-powder or bran from the rice with washing, and along with steeping, we raise the moisture content of the rice to as close to a fixed ideal ratio as possible. Naturally, since the initial water content of the rice varies greatly by the milling ratio (seimaibuai) and the length of time since milling, we can’t just soak the rice for the same amount of time every day. We have to adjust it. We also have to take the ambient humidity and temperature into account. Thus, the conditions differ every day.

So, first we have to measure the current content, and then calculate backwards from the absorption rate to find the best soaking time to achieve our target moisture. Absorption time is a calculated to the second, so to keep it under control we wash the rice by hand in small, 10 kilogram batches. After soaking, we remove excess surface water with a centrifuge, and confirm water absorption by weight. We repeat this work over and over, tweaking the soaking time as we go. If we have 600 kilograms of rice to process, we will do it 60 times.

The battle that is brewing saké is lost without proper preparation.

Follow the Sense of Touch (Making Kōji 1)

The information we can gather through touch is far more precise than anything measuring instruments can tell us.

Growing kōji on rice takes a full two days and nights. The first day’s work starts with stirring, breaking up, and spreading the steamed rice, and these sensors, our hands, tell us not only how the temperature and moisture change, but the firmness, the texture of the surface, and other important indicators of the rice’s condition. That all helps identify the perfect time to add the kōji spores. Naturally, we carefully record time and weight measurement data, but we’ve found that our sense of touch is the most reliable indicator.

Our work in the kōji muro, the room where rice is inoculated with kōji and it’s allowed to grow, brings us physically close to the rice, and the tables where the rice is laid for kōji inoculation are called toko, meaning “bed.” The act of spreading the kōji spores on steamed rice is also called tanetsuke or tanegiri, meaning “mating.” Clearly, our forefathers found something almost sexual in this work, in that the relationship between human and rice in the kōji muro is akin to that in the marriage bed. Everyone who’s had the privilege to make rice kōji senses this connection, and so we resist any kind of automation in this vital, physical work.

In Sync with Microorganisms (Making kōji 2)

When people talk about making saké, they often bring up the simultaneous work of saccharification and fermentation by kōji and yeast, two microorganisms. The reality of making saké requires work that’s done on the human schedule, and work that has to meet the ideal conditions of those microorganisms.

Intense observation is essential to make sure the process goes well, and in a real sense you have to try and synchronize with these tiny living things. Yet, there are limits to what humans can do even with hard work, so in this realm we get help from the IT world. For example, we take data on changes in rice temperature over time as measured by a wi-fi enabled thermometer, and share it with every kurabito in an app on their smartphones via the cloud, so everyone knows in real-time when the best time to start their assigned task is. Constantly sharing data like this helps the team synchronize with each other, as well as with those microbes.

Make Necessary Extra Effort (Shikomi)

The process of building the mash, or shikomi, in saké making is designed to encourage the total number of yeast cells to increase through cell division. Our forefathers developed the sandan-jikomi, a mash building process where the volume of the moto (or shubo, fermentation starter) is increased in three stages, as the most efficient way of increasing the total number of yeast cells.

After the yeast multiplies to its upper limit in a small shubo tank, it’s transferred to a large tank to start the moromi (mash), and sandan-jikomi begins. The three stages are called hatsu-zoe, naka-zoe, and tome-zoe. Each stage takes one day, and includes the addition of rice kōji, steamed rice, and water into the tank in increasing amounts. There is a period between hatsu-zoe and naka-zoe, called odori, when the mash is allowed to rest, so the whole process takes four days. We essentially follow this standard procedure, with one difference. For hatsu-zoe, we use a smaller tank, different from the one for naka-zoe and tome-zoe, to match its smaller amount.

The reason for this is that building hatsu-zoe in a tank with enough space for tome-zoe is difficult, as the tank is simply too big. It creates too much surface area for the mash. With such a large vessel, the kōji and yeast have trouble finding balance, and the rhythm of parallel multiple fermentation (i.e. simultaneous saccharification and fermentation) is thrown off, meaning the harmony that we are trying to establish falls apart. Every great violinist started playing as a child on a tiny violin and so it is with our mash. Thus, while usually saké makers get by with transferring their shubo to a new tank only once, we have to do it twice.

Taking the time and trouble to divide mash building into three stages is the Japanese way, but we go that extra mile by adding even more trouble. But it’s necessary to achieve that Gangi flavor.

Listen to the Mash

There’s talk about how playing music during fermentation helps make better saké, and apparently some breweries play Mozart to their mash, but we feel something’s off there. Isn’t it the other way around? The kurabito shouldn’t be making the microorganisms listen to music, they should be listening to the music of the microorganisms! It may be difficult for the ears to pick up, but when you are inside the fermentation room you can sense in the atmosphere a complex polyrhythm in the air like an Indonesian gamelan, a universe of sound created by saccharification and fermentation.

Managing the mash entails graphing the curve of sugar reduction (toke) and alcohol buildup (kire) over time, adding water, and finding the best time on that curve to stop fermentation and press the saké. That requires daily sampling to analyze and quantify the alcohol levels, sugar content, acidity, amino acid levels, and so on. This offers a complex understanding of the fermentation situation, and yet often there is a gap between the numbers and what our senses tell us. Brewing saké is not simply a numbers game. Our kurabito spend every day watching over the mash and seeing how it evolves, feeling the soundless whispers of it. Being there, in that space, to get a sense of how fermentation is going, is shockingly similar to being a parent, with one ear always open to the sound of their infant’s sleeping breath.